1

/

of

1

MTI Corporation

LiFePO4 (Lithium Iron Phosphate, LFP) Powder for Li-ion Battery Cathode, 150 g/bottle - LIB-LFPO

LiFePO4 (Lithium Iron Phosphate, LFP) Powder for Li-ion Battery Cathode, 150 g/bottle - LIB-LFPO

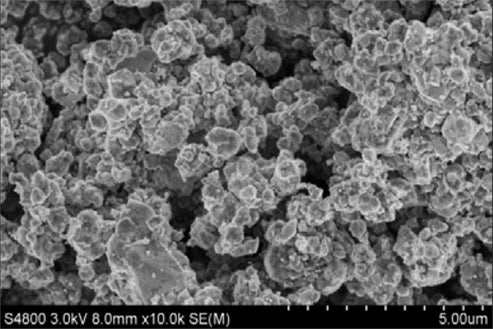

LiFePO4 (LFP) powder coated by Carbon with high cyclability for Li-ion battery cathode, 150 g/bottle, vacuum-sealed in a plastic bag.

Specifications:

Specifications:

|

Physical Properties |

||

|

|

D10 (μm) |

|

|

D50 (μm) |

|

|

|

D90 (μm) |

|

|

|

|

||

|

Tap Density (g/cm3) |

|

|

|

Packing Density (g/cm3) |

|

|

|

Specific Surface Area (m2/g) |

|

|

|

Moisture (%) |

|

|

|

|

C (%) |

1.15 ± 0.25 |

| Li (%) |

4.40 ± 0.50 |

|

| Fe (%) |

34.5 ± 1.0 |

|

|

P (%) |

19.5 ± 1.0 |

|

|

O (%) |

40.4 ± 0.50 |

|

|

impurity (Na, Ca, Ni) (%) |

≤ 0.01 |

|

|

|

||

| Electro-Chemical Properties | |

| 20 Ah Pouch Cell with LFPO-S21 Cathode | |

| Cathode Surface Density (g/m2) |

|

| Cathode Packing Density (g/cm3) |

|

| Internal Resistance (mΩ) |

|

| Efficiency at 0.1C First Cycle (%) |

|

| Specific Capacity at 0.1C First Cycle (mAh/g) |

|

| Capacity versus Discharge Rate | |

| Capacity versus Cycle Number | |

| 10 Ah Pouch Cell (High Discharge Rate) with LFPO-S21 Cathode | |

| Capacity versus Discharge Rate |

|

|

|

Application Notes:

- Please click to see Procedure for Preparing Anode & Cathode Electrode Slurry.

- Please keep the powder in the vacuum box to avoid moisture.

- Please bake the powder in a vacuum oven at 120 - 150 °C before making slurry and coating to ensure max capacity.

- This product is not manufactured by MTI. We only sell small quantity to the researcher for developing new battery. If you have any question on IP conflict, let us know. We will forward the question to the manufacturer.

Share